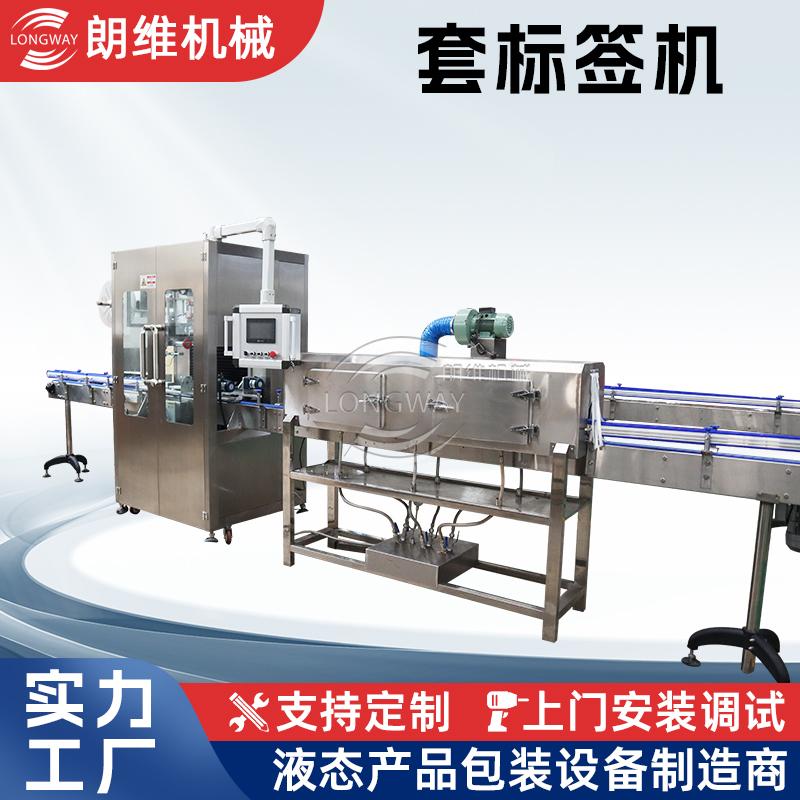

Sleeve Shrink Labeling Machine,Sleeve Labeling Machine,Shrink Labeling Machine

|

Input Power |

3.0KW |

|

Input Voltage |

3, 380/220VAC |

|

Production Efficiency |

250 bottle/min |

|

Size of Host Machine |

2100L*850W*2000H |

|

Applicable Diameter of Bottle Body |

28 mm-125mm |

|

Applicable Length of Label |

30 mm250mm |

|

Applicable Thickness of Label |

0.03 mm0.13 mm |

|

Applicable Internal Diameter of Paper Tube |

510adjust it at will |

All-cover type stainless steel host machine: the whole machine is waterproof as well as rustless.

Adjustable cutter head: uniquely cyclotron cut-off, double sided cutting edge with a long service life.

Single positioning centre guide pillar: a more stable for label delivery.

Synchronous bottle divider: a more stable transmission for bottle.

Bottom set of label brush: a more precision for casting label.

Label-controlling electric-eye shelf: unique combination of tail and electric-eye to improve the precision for cutting off the membrane materials.

Push-button control cabinet: a more humanized operation.

Independent feeding material shelf: the position of the material shelf is optional at will.

Electrical Appliance Configuration Specification

It adopts PLC programmable controller, imported servo motor, servo driver, frequency converter and transducer; besides, it adopts the positioning module to ensure the casting label precise, rapid and stable.

Applicable Bottle Types

Various kinds of bottle types, for example: round bottle, square bottle, flat bottle, curved bottle and cup-shaped, etc